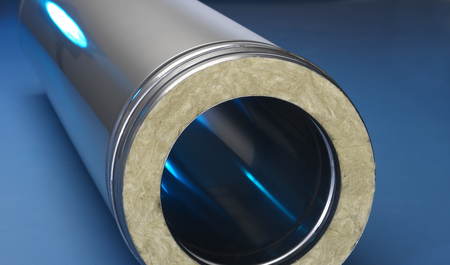

A double-walled, modular and pre-insulated flue gas system made of stainless steel. Suitable for high exhaust gas temperatures and high exhaust gas pressures, especially for industrial applications, gas or diesel engines, emergency power and emergency power systems.

Perfect for all industrial and commercial flue gas applications up to an overpressure of 5000 Pa.

Haven't found the right product yet? Use our online assistant to find the right product for your needs.

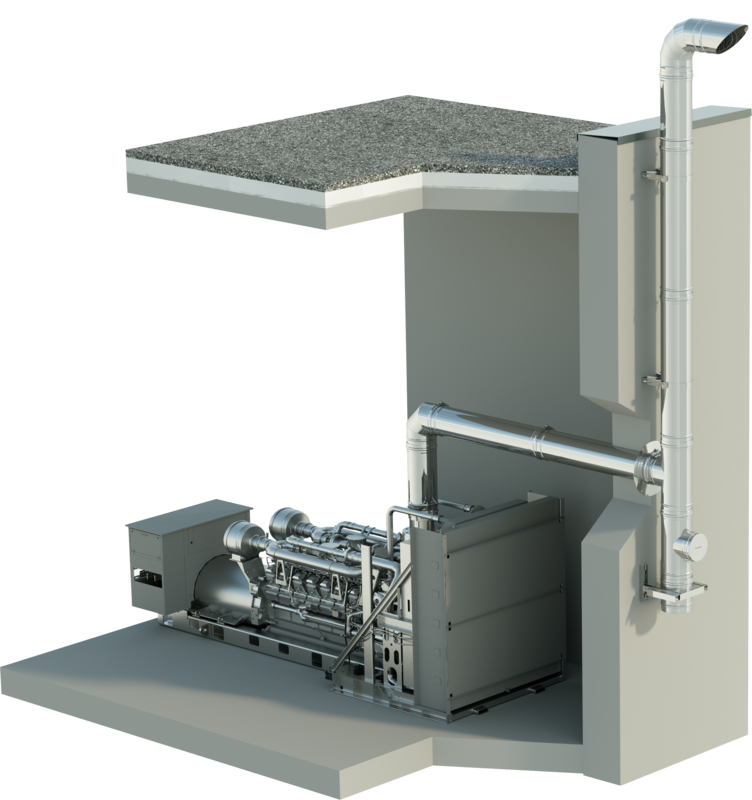

You want to get the maximum return from generator sets and CHP applications. This also includes proper disposal of gases and other emissions. While architects and building owners are not interested in exhausts and annoying installation processes. At Schiedel we can help you engineer the perfect exhaust solution!

Mitigate risks on the critical project path and elevate your project success with Schiedel's Center of Engineering. Our expert team ensures precision and efficiency, safeguarding your flue gas project from start to finish.

Looking for expert guidance? Connect with our knowledgeable sales consultants in your region to find the perfect solution for your needs!

| Basic data (dimensions, weight & co.) | |

Wall thickness per diameter (internal) |

0,5 - 1,0 mm |

Wall thickness per diameter (outside) |

0,5 - 0,7 mm |

| Application | |

Flue gas temperature (dry) |

≤ 600 °C |

Material (Inner liner) |

AISI 316L-EN 1.4404 |

Material (Insulation) |

Mineral fibre |

Material (Outer case) |

Material No.: 1.4301 |

Thermal resistance (m²k/w) by insulation thickness |

0,37 - 0,56 m²K/W |

| General product features | |

Operating |

Dry, Negative pressure (N), Positive pressure (P-H) |

Room sealed |

No |

Area of application |

Heating systems, Generators, Emergency generators |

Occupation |

Single, Multi |

Suitable for passive house |

No |

Heating technology |

High pressure 5000 Pa, Condensing boiler technology, Low temperature technology |

At Schiedel, service is more than just a friendly voice on the phone. Service is an essential part of the Schiedel total package. In addition to product quality, safety, reliability and innovative strength as well as a good price-performance ratio, customer satisfaction is significantly influenced by our service. Below you will find an overview of matching services.

From designs to seamless execution, we bring your projects to life with precision and expertise. Explore how Schiedel Center of Engineering can elevate your next project.

Are you looking for tips or a sales advisor in your area? Our sales advisor search will help you.

Find the right contact person for our customer center, customer service or technical advice.

Our online databases give you access to over 4,000 drawings for our stainless steel, ceramic chimney and stove systems. Register and download now.

Select the products you want and order with just a few clicks. Save your shopping basket for future orders.

The correct calculation of your required offset forms the basis of a correct functioning flue any combustion system.

Unlock seamless connectivity of technical product data with 2BA data integration from Schiedel—where you can enhance your building solutions!