The best flues for Biomass

(Washington, Tyne and Wear, 10. September 2017) Biomass has staked its claim as a popular renewable heat source for the commercial sector, spurred on by the Renewable Heat Incentive (RHI) and businesses’ desire to be greener and more sustainable. Even without the cash-back incentives, wood presents a renewable and consistently priced heat source, attractive for any organisation with a long-term eye to the future.

Biomass boilers and their efficiency.

The boiler itself is only one part of the story, however, choosing the right flue will support efficiency claims, while ensuring the heating system works in its specific application.

Flue rules

All biomass flue applications over 50kW require a designer/installer to adhere to the relevant regulations and standards, such as BSEN 15287 and BSEN 13384. Additionally, consideration to the Clean Air Act may be required, something that is becoming particularly important as air quality in our towns and cities comes under scrutiny.Best flues for biomass

The best flue for any biomass system is one that can cope with some condensate, as well as being soot fire resistant – for example, on a steel system, installers should be looking for a product that has both a ‘W’ (wet) designation as well as a ‘G’, which covers soot fire resistance and means the product has been tested at 1000ºc for 30 minutes.One option is to choose a ceramic system, suitable for wood biomass, multi-fuel oil and gas. The inner ceramic liner is insulated with rock wool and contained in a preformed concrete block.

The same modular size as masonry building blocks, ceramic chimneys are usually designed to bond into adjacent brick or block work. For a rock mineral wool system, it is recommended that liners and chimneys are tested and approved to BS EN1457-2 for low temperature applications with a WC rating (condensate resistance), as well as BS EN1457-1 for high temperature applications.

A general all-round product that covers stoves, biomass appliances and open fires is our ICS twin wall insulated chimney system (which is also suitable for gas, oil and multi fuel). It is suitable for residential through to large commercial applications, with continuous operating temperatures up to 450c.

Victoria Hospital, Kirkcaldy, Fife

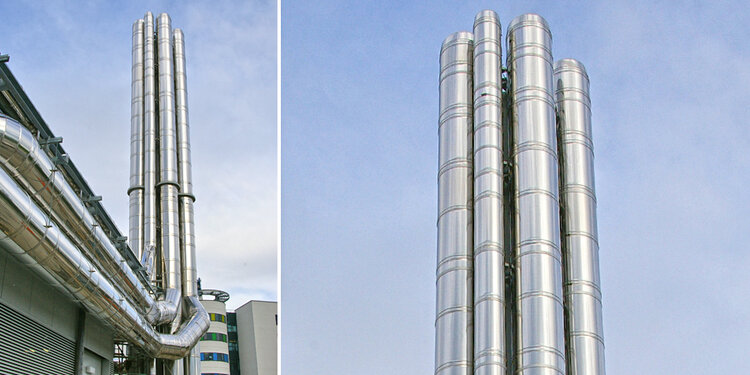

The newly built Victoria Hospital required a challenging chimney installation, designed to service two biomass boilers, four diesel generators, three steam boilers and a CHP system. Schiedel’s ICS and ICS 5000 flues were used, chosen for their versatility across a range of different heating systems.Both systems are twin wall stainless steel with and insulated inner layer, suitable for gas, oil and biomass. ICS 5000 in particular works well with CHP and features a pressure gasket, TUV approved to 5,000Pa.

The appliances used were from Hoval, Froling Lambdamat, Certuss Steam Generators, Dresser Rand and FG Wilson.

The flues were supported on a 19m high supporting structure, with CHP a late addition to the scheme after the main mast and original flues had been specified. Schiedel Chimney Systems integrated the additional flues into the overall structure in an economically and efficient manner.

For the most part, boiler and stove manufacturers will provide advice on flue sizing for their products or, like Schiedel, chimney and flue specialists should be able to provide chimney sizing, EN13384-1 & EN13384-2 have specialist online calculators to help with specifications for single appliances.

Existing chimneys and flues: Existing chimneys can be utilised for a new biomass system, in fact one of the big benefits of biomass is the fact it can be retrofitted to an existing oil or gas system, working with standard radiators or underfloor heating.

Where an existing chimney or flue is used, it must be inspected for deterioration. In order to maximise efficiency and ensure the correct diameter is being used for the appliance, a flexible or rigid chimney liner can be used, so long as the products have been tested and approved to EN1856-2 for the application.

Flue location

Flues running inside a building will not need planning permission, but those sited externally must adhere to the following rules:- Flues on the rear side or side elevation of a building are allowed, but care should be taken to ensure they meet the termination specification for solid fuel appliances and/or the clean air act where required.

- If the building is listed or in a designated area, even if you have permitted development rights, it is advisable to check with your local planning authority before a flue is fitted.

- In a conservation area or World Heritage site, the flue should not be fitted on the principal or side elevation if it would be visible from a highway.

More related content

Guide

Biomass boiler starter kits

There is a increasing use of Biomass boilers for commercial and residential situations, but what is a Biomass boiler? Biomass as a definitio...

News

Biomass Installation at Hartpury College.

Biomass, being an organic material that comes from plants and animals, is an ideal source of energy as it’s renewable. Which is why the Spor...

News

Chimney system for Raigmore Hospital

Schiedel Chimney Systems were involved in a 3 phase project for Raigmore Hospital. The project saw a number of boilers and flues installed i...