Chimney system for Raigmore Hospital

(Washington, Tyne and Wear, 16. July 2017) Schiedel Chimney Systems were involved in a 3 phase project for Raigmore Hospital. The project saw a number of boilers and flues installed in separate phases.

Commercial installation

The initial installation was of 2 Biomass Boilers, installed within the existing concrete chimney. The flues comprised of 2 x 600mm ID biomass boiler flue systems. The installation process started at the uppermost platform working down. This meant hoisting 10 x 1000mm pipe sections through the centre access opening of the chimney

The ground level installation comprised of a base support plate for each of the flues, above which was positioned a clean out section with access door. Above this the flues continued vertically to platform level 1. The flue sections were of a simple male spigot, female socket “push-fit” jointing arrangement with external locking bands, which made it very easy to install.

At each platform, the flue systems were supplied with support plates, which were be secured to the open mesh flooring of the platform. At mid height between the platforms an additional adjustable wall bracket was installed to secure the flue back to the inner wall of the chimney.

This continued throughout the height of the chimney to capping plate level. Externally, the flue continued to terminate with efflux cones and pipe sections painted matt black to match the existing liners. The flue penetrations were also be supplied with new weather aprons and storm collars.

Phase 2

The second installation comprised of the 2 x 600mm ID horizontal biomass boiler flue systems. After initial set up work, the flue systems were installed by means of purpose made flanged adaptors bolted to the biomass ductwork. The flues then ran horizontally and incorporated 45° rolling offsets before making the connection with the concrete chimney liners.

Phase 3

The final phase saw the erection of 2 x 300mm ID dual fuel boiler flue systems and 1 x 450mm ID flue system. Purpose made adaptors were made to be connected to the horizontal exhausts of the Viessmann Dual Fuel Boilers. Each flue rose vertically before turning through 90° and exiting the Energy Centre via the penetration positions. Externally, the flues travelled horizontally to make connection with the 90° tees installed on the mast.

Within the Energy Centre a purpose made adaptor connected to the high level exhaust of the biomass cyclone unit. The flue then offset vertically to clear the cladding rail before turning through 90° and exiting the Energy Centre via the penetration position.

Again, externally, the flue travelled horizontally to make connection with the 90° tees installed on the mast.

More relevant content

News

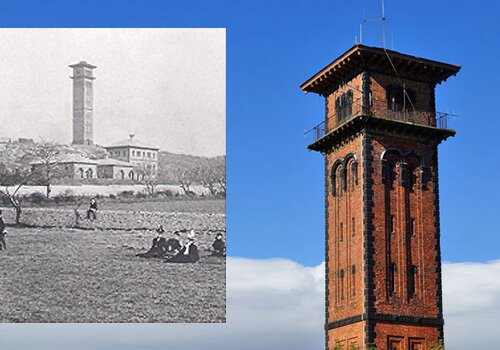

Cleadon Water Tower Chimney

Looking at local landmarks near our Washington factory, an interesting one has popped up (excuse the pun) at Cleadon, a village located near...

News

Comprehensive stove and chimney installation course

Schiedel have introduced a new course, which is designed for transferable skills and will allow you to become competent to install a stove a...

News

Casa TTYA reveals our Garden Fireplace 500 model!

We are delighted to announce that Irene Agbontaen has revealed our 500 Model.